Mosaic has been used since ancient times as flooring and in the decoration of walls and walls because it provides a unique and singular decorative personality.

Today it is integrated in numerous projects of decoration of houses and buildings of new construction or reforms, in outstanding rooms and entrances, in corridors, bathrooms and, of course, also in exteriors.

At Decorarconarte.com we give shape to your project adapting to your needs.

Completely handmade and meticulous work

The most important tool used by our craftsmen are their hands, with the help of manual tools.

The mosaic is an ancestral art, which consists of the union of fractions of stones (marble or vitreous paste) of cubic form, called tesserae.

The technique used

The technique is the “opus teselarium”, a mosaic of cubic stone tesserae.

We work with 5, 8 and 10 mm tesserae. Different sizes can also be combined to achieve greater precision in some details.

Method

There are several methods (direct, indirect, engraving and the use of pebbles). In our workshop we prefer to use the Indirect Method; this consists of placing the tesserae on the design and once it is finished, it is inverted so that the resulting surface of the mosaic is completely smooth (the opposite of the direct method).

In terms of appearance. It can be an aged mosaic, unfinished or with gaps, polished, polished or any other aspect that the client may suggest. The finish will depend on the application of the mosaic.

Floor or wall mosaics.

The destination of most of the mosaics is usually either for paving on the floor, or as wall decoration, inlaid or as a hanging picture.

For the floor:

Floor mosaics are of great beauty and give a sublime look to any interior or exterior space. The tesserae are usually preferred with polished visible faces.

Their thickness can be varied according to requirements. to reduce transport weight and increase strength and elasticity, a layer of polycarbonate is applied in a cellular form.

The consolidation of the mosaic thus has, on its reverse side, a synthetic laminate finish covered with a layer of Chinese adhesive for better adhesion and fixing. It is suitable for outdoor exposure and for trafficable areas except for vehicles and heavy machinery.

For walls:

The wall mosaic can be either for embedding or for hanging. The thickness of the mosaic can be made to customer specifications. The back and edges are finished with rustic mortar.

Materials used

The materials used are tesserae of natural stones and various marbles. For some special colours, glass paste and resins are used, just as they were used in ancient times.

The range of colours is almost infinite. The use of vitreous paste can be combined with marble to achieve bright and cheerful colours, giving the mosaic luminosity and movement.

Time of production

The times vary depending on the project. They can be between 2, 4 and 8 weeks.

Instructions for laying a mosaic floor tile

The material we recommend for laying the mosaic is any type of flex-super glue cement.

For the installation of the mosaic it is advisable to follow the following steps:

STEP 1: The floor where the mosaic is to be laid must be strong, level or mortar-troweled and free of dust.

STEP 2: It is recommended to provide an expansion joint around the perimeter of about 3-4 mm in order to avoid lateral thrust from the surrounding work (not from the piece itself) and expansion due to its exposure to the outside.

STEP 3: Next, apply the glue cement with a notched trowel with double gluing, both on the surface and on the back of the mosaic. This will be enough to perfectly adhere the piece.

STEP 4: The next day it is advisable to seal the perimeter joint with a polymer sealant.

Maintenance of the floor mosaic

It is advisable to clean the mosaic with clear water and in any case with green soap or neutral soap.

The use of aggressive chemical products or other detergents is not recommended.

As far as maintenance is concerned, these types of pieces do not need any treatment, it is only advisable to apply a layer of water-repellent protector with a wet look or any type of mineral oil every few years (2 or 3 years) in order to maintain the vividness of the colour, especially on pieces exposed to the exterior.

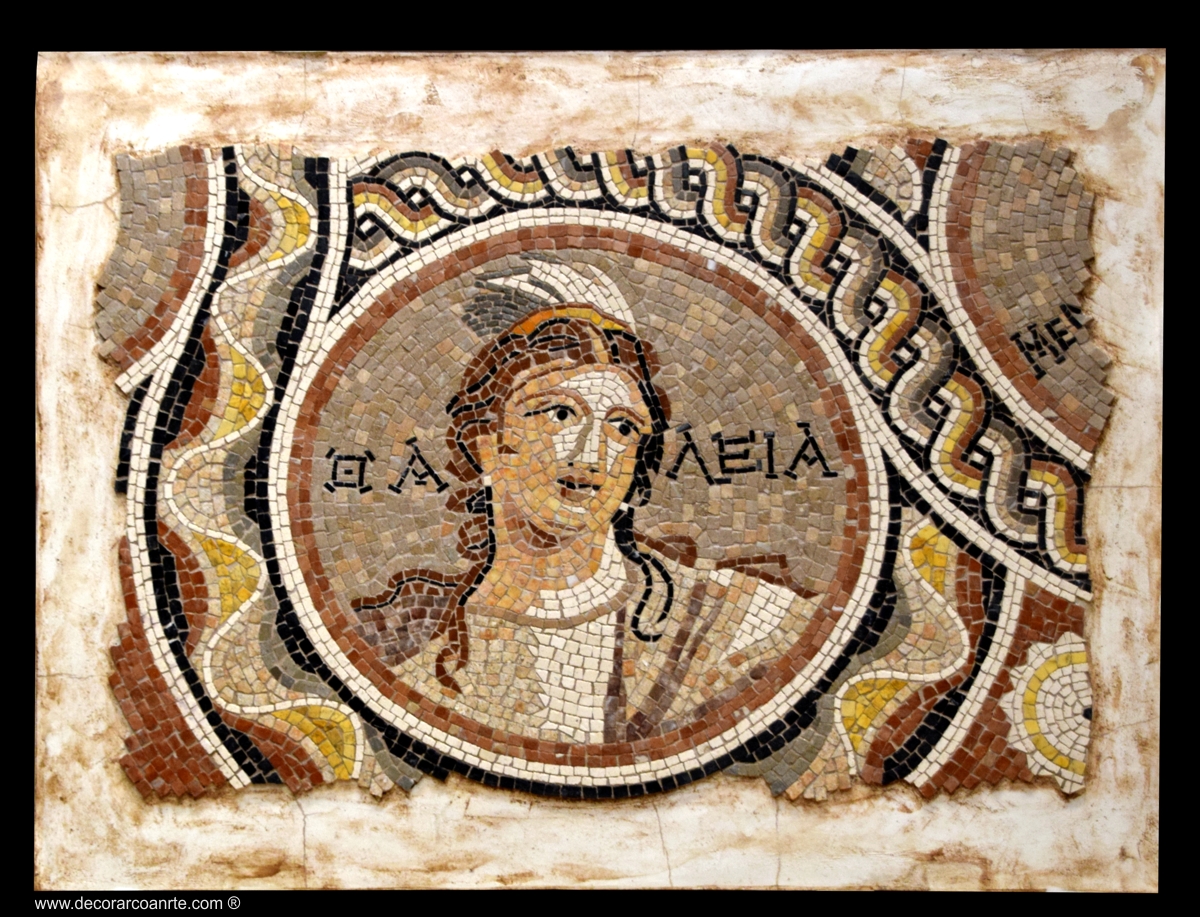

The themes

We specialise in the reproduction of Roman mosaics, both figurative and geometric. We also approach any style with the same delicacy and expertise. Ask us about your project without obligation.

In addition to the models that we offer in our catalogue, we also make reproductions of Roman, Byzantine mosaics or mosaics inspired by historical, mythological or artistic themes in general. Click here to see photographs of original mosaics where you can find the motif that best suits your project. (See).

It is also possible to create two-colour mosaics with motifs of Greek ceramic drawings and paintings, with very good decorative results. (See)

We also offer partial or total reproductions of the mosaic of the Lovers of the Iberian-Roman city of Castulo. (See)

How they made it in ancient Rome

The Romans learned the art of mosaics from Greece and Asia Minor from the 2nd century BC after the conquest of these regions. Such was the success of this decorative art that it became an essential element in the decoration of the Roman domus of the wealthy classes.

The material used to make mosaics was tesserae, cubes cut in different colours and from different materials, mainly stone, both calcareous rocks or marble and precious stones (lapis lazuli), glass and coloured vitreous pastes, ceramics, and even metals such as gold.

There were various styles of mosaics, the most striking being those that formed complex polychrome drawings with a pictorial quality and in which relief effects were achieved with shading: opus tessellatum, with cubes 10 mm in size, and opus vermiculatum, with even smaller tesserae arranged in worm-like undulations, hence the name (vermis = worm).

To make the mosaic, the ground was previously levelled and prepared with several layers:

1. Statumen: first layer of stones the size of a fist.

2. Rudus: second layer composed of 3 /4 parts of gravel and one part of lime.

3. Nucleus: third layer with 3 /4 parts of crushed pottery and one part of lime.

The mosaic was laid on top of this layer, which was made in several stages:

1. The caementarius (mason) levelled the floor and waterproofed it with opus caementicium (the Roman concrete or cement made from mortar and stones of all kinds).

2. When the opus caementicium was set, the pictor imaginarius (painter) drew the design on the floor.

3. The musivarius would mark and paint the areas of the design and the tesselarius would cut and carve the tesserae, preparing them to the size and shape required for their precise placement.

4. The tesserae were placed either first on a board with which they were pressed to fix them to the floor, or directly on the damp floor. The holes were filled with a thin layer of mortar and finally, to get a shiny and smooth finish, they were polished with grit and marble dust.

We give shape to your project

If you would like a budget with stockings or a personalised motif, please contact us without obligation.